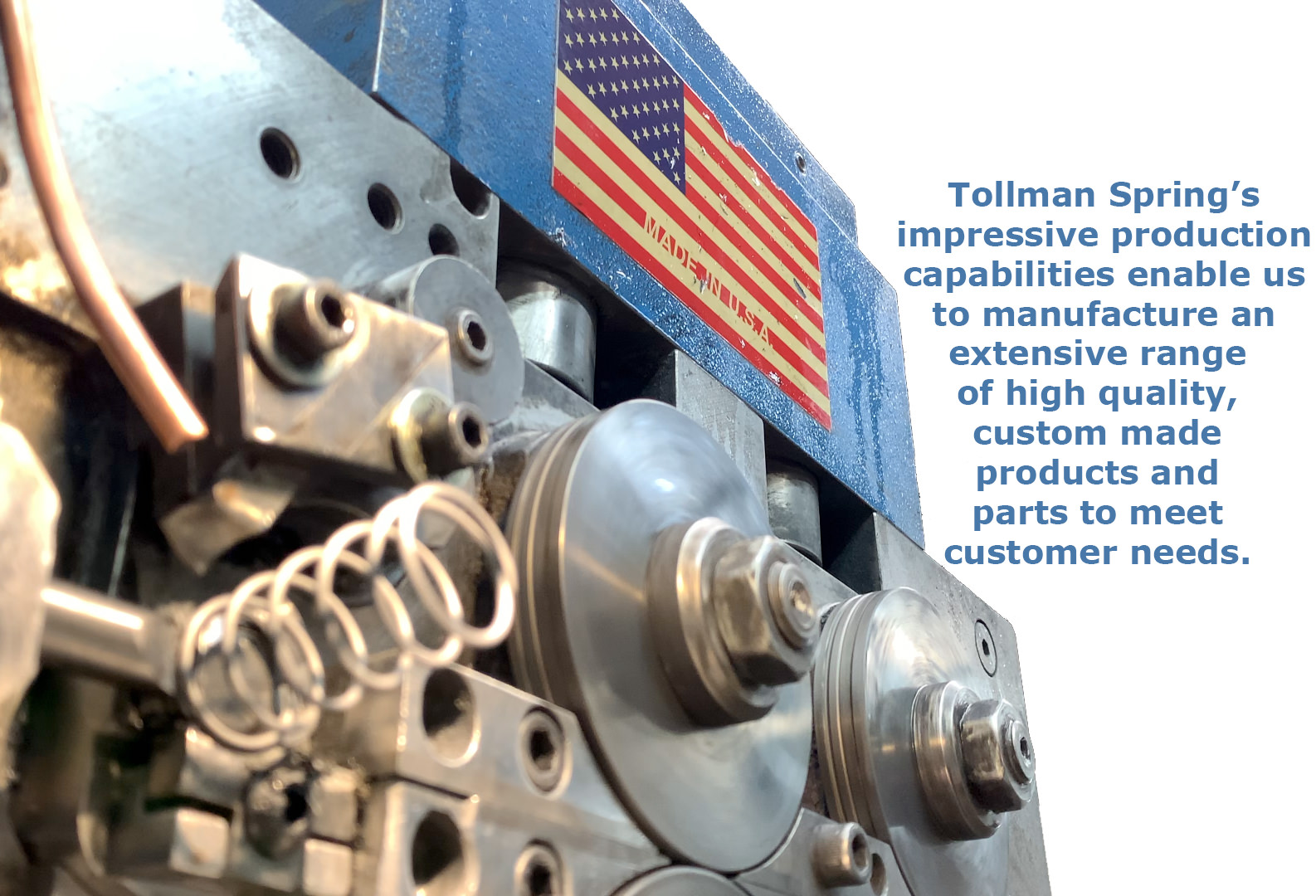

THE SOURCE FOR QUALITY AND SERVICE SINCE 1945

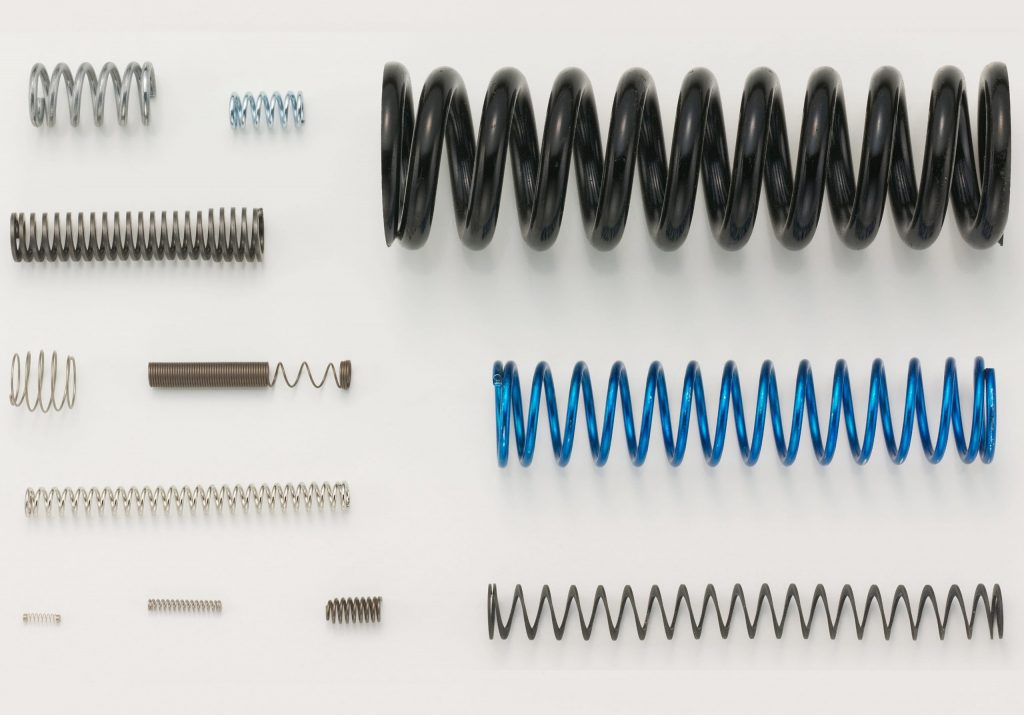

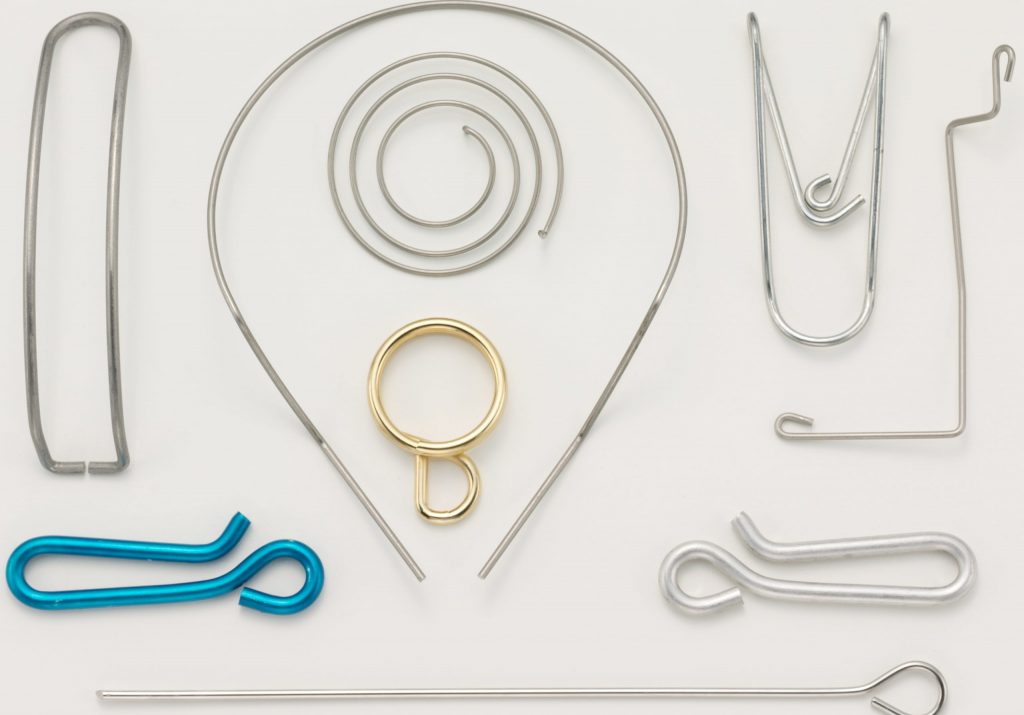

Tollman Spring Company is a world-class manufacturer of high quality compression, extension and torsion springs, four slide stampings and wire forms used throughout the United States, China, Europe, India and South America. Known around the globe for its commitment to quality and service, Tollman operates out of three state-of-the art manufacturing facilities in Bristol, Connecticut, where more than 100 highly skilled employees work closely with Tollman customers ranging from some of the world’s largest companies, such as General Electric, to a local manufacturer of bird feeders.

Tollman specializes in customized wire forming, fourslide stamping and spring manufacturing of all types.

Contact Us

We’re ready, Let’s talk.

Contact info

Address

91 Enterprise Drive

Bristol, 06010

Connecticut, USA

Email us

Chuck.Pechulis@tollmanspring.com

Call Us

860-583-1326

Fax Us

860-589-8733

Linkedin

Facebook-f

Twitter

Youtube